Modules-ka Heerkulka Korontada iyo Codsigooda

Marka la dooranayo walxaha N,P ee semiconductor-ka ee ku shaqeeya thermoelectric, arrimaha soo socda waa in marka hore la go'aamiyaa:

1. Go'aami xaaladda shaqada ee walxaha N,P ee semiconductor-ka ee ku shaqeeya heerkulka. Sida waafaqsan jihada iyo cabbirka qulqulka shaqada, waxaad go'aamin kartaa qaboojinta, kululaynta iyo waxqabadka heerkulka joogtada ah ee fal-galiyaha, inkastoo habka ugu badan ee loo isticmaalo uu yahay habka qaboojinta, laakiin waa in aan la iska indho tirin kulaylinta iyo waxqabadka heerkulka joogtada ah.

2, Go'aami heerkulka dhabta ah ee dhamaadka kulul marka la qaboojinayo. Maadaama walxaha N,P ee semiconductor-ka ee thermoelectric-ka ay yihiin qalab kala duwan heerkulka, si loo gaaro saameynta ugu fiican ee qaboojinta, walxaha N,P ee semiconductor-ka ee thermoelectric-ka waa in lagu rakibaa radiator wanaagsan, iyadoo loo eegayo xaaladaha kala-baxa kulaylka wanaagsan ama xun, go'aamiya heerkulka dhabta ah ee dhammaadka kulaylka ee walxaha N,P ee semiconductor-ka ee thermoelectric-ka marka la qaboojinayo, waa in la ogaadaa in saameynta kala-baxa heerkulka awgeed, heerkulka dhabta ah ee dhammaadka kulaylka ee walxaha N,P ee semiconductor-ka ee thermoelectric-ka uu had iyo jeer ka sarreeyo heerkulka dusha sare ee radiator-ka, badanaa ka yar toban meelood meel, in ka badan dhowr darajo, toban darajo. Sidoo kale, marka lagu daro kala-baxa kulaylka ee dhammaadka kulul, waxaa sidoo kale jira kala-bax heerkul ah oo u dhexeeya booska qaboojinta iyo dhammaadka qabow ee walxaha N,P ee semiconductor-ka ee thermoelectric-ka.

3, Go'aami jawiga shaqada iyo jawiga walxaha N,P ee semiconductor-ka ee ku shaqeeya heerkulka. Tan waxaa ka mid ah in lagu shaqeeyo meel faaruq ah ama jawi caadi ah, nitrogen qalalan, hawada taagan ama socota iyo heerkulka deegaanka, kaas oo laga tixgelinayo cabbiraadaha dahaarka kulaylka (adiabatic) iyo saameynta daadashada kulaylka.

4. Go'aami shayga shaqada ee walxaha N,P ee semiconductor-ka ee thermoelectric iyo cabbirka culeyska kulaylka. Marka laga soo tago saameynta heerkulka dhammaadka kulul, heerkulka ugu yar ama farqiga heerkulka ugu badan ee uu gaari karo is-goysku waxaa lagu go'aamiyaa labada xaaladood ee aan culayska lahayn iyo adiabatic, dhab ahaantii, walxaha N,P ee semiconductor-ka ee thermoelectric-ka ma noqon karaan kuwo dhab ahaan adiabatic ah, laakiin sidoo kale waa inay lahaadaan culays kuleyl ah, haddii kale macno malahan.

Go'aami tirada walxaha N,P ee semiconductor-ka ee thermoelectric-ka. Tani waxay ku salaysan tahay awoodda qaboojinta guud ee walxaha N,P ee semiconductor-ka ee thermoelectric si ay u buuxiyaan shuruudaha farqiga heerkulka, waa inay hubisaa in wadarta awoodda qaboojinta walxaha semiconductor-ka ee thermoelectric-ka ee heerkulka hawlgalka ay ka weyn tahay awoodda guud ee culeyska kulaylka ee shayga shaqeeya, haddii kale ma buuxin karto shuruudaha. Inertia kulaylka ee walxaha thermoelectric-ka aad bay u yar tahay, ma aha wax ka badan hal daqiiqo oo aan lahayn culays, laakiin sababtoo ah inertia culayska (badanaa sababtoo ah awoodda kulaylka ee culayska), xawaaraha shaqada ee dhabta ah si loo gaaro heerkulka la dejiyay aad ayuu uga weyn yahay hal daqiiqo, iyo ilaa dhowr saacadood. Haddii shuruudaha xawaaraha shaqadu ay ka badan yihiin, tirada tuulmooyinka ayaa ka badan doonta, awoodda guud ee culayska kulaylka waxay ka kooban tahay awoodda kulaylka oo dhan iyo daadinta kulaylka (heerkulka oo hooseeya, daadinta kulaylka oo sii weyn).

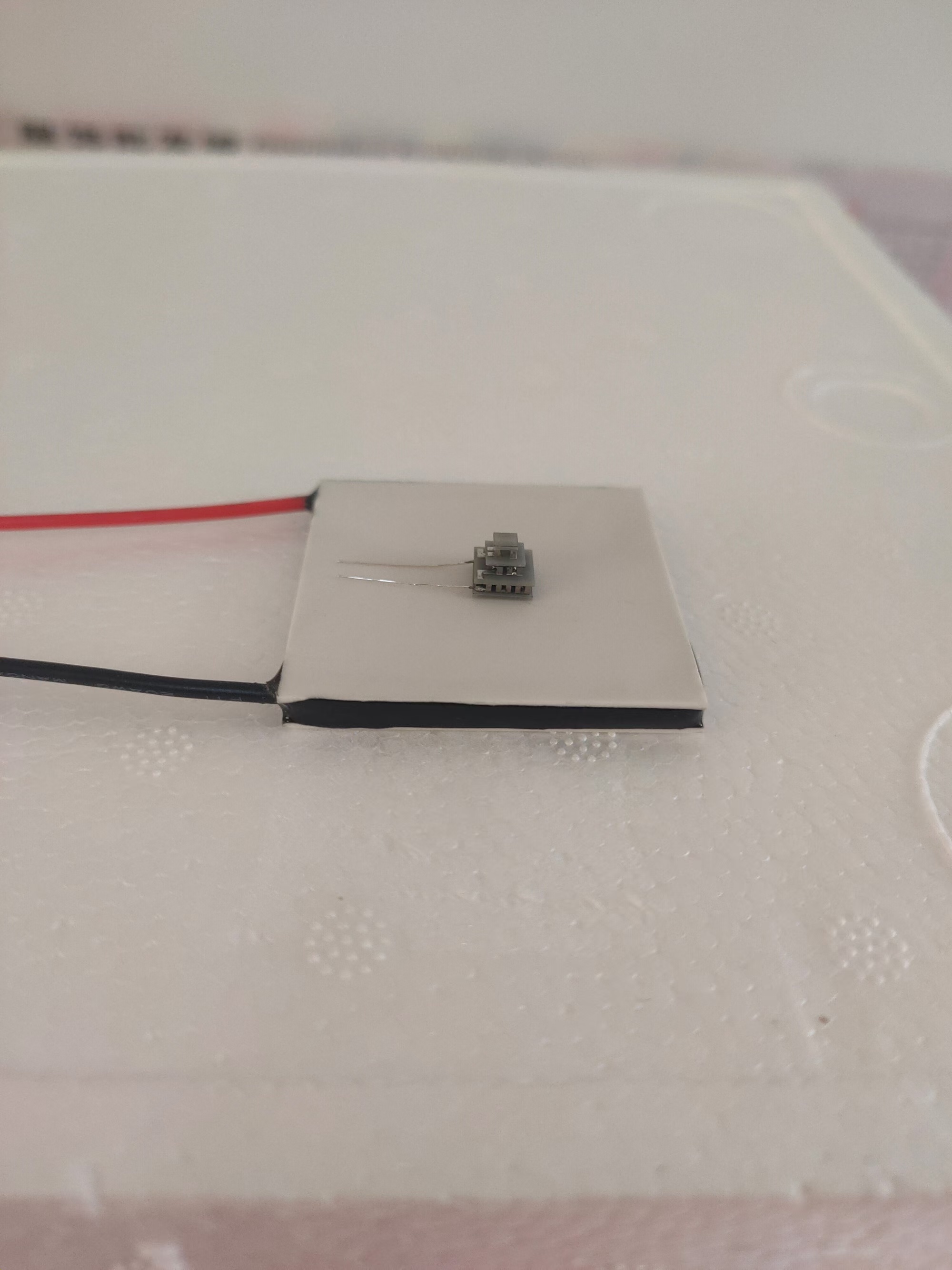

TES3-2601T125

Imax: 1.0A,

Umax: 2.16V,

Delta T: 118 C

Qmax: 0.36W

ACR: 1.4 Ohm

Cabbirka: Cabbirka salka: 6X6mm, Cabbirka sare: 2.5X2.5mm, Dhererka: 5.3mm

Waqtiga boostada: Noofambar-05-2024