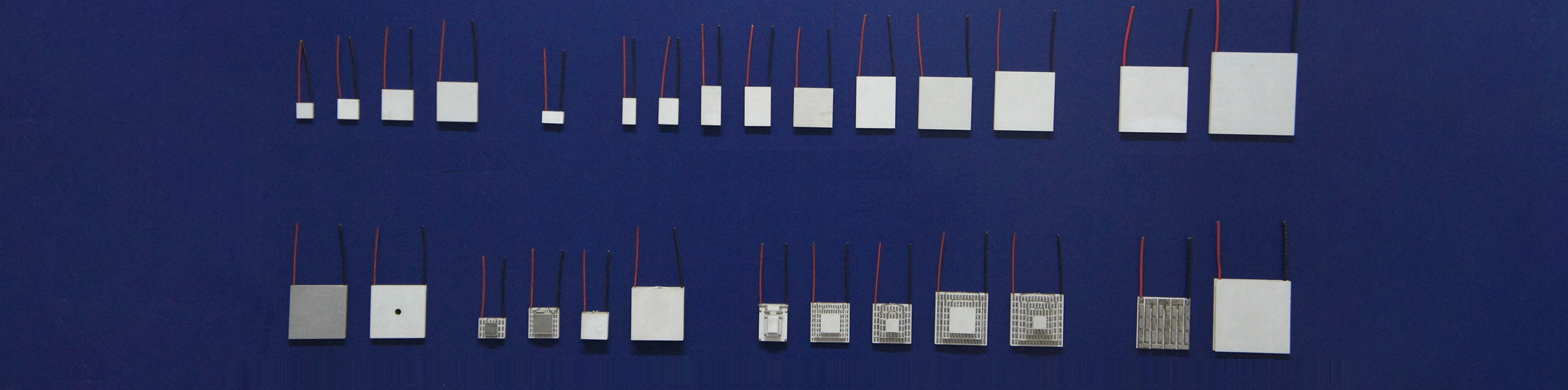

Modules-ka qaboojinta heerkulka, module-ka thermoelectric, module-ka TEC, qalabka peltier Habka rakibidda

Guud ahaan waxaa jira saddex siyaabood oo lagu rakibi karomodule-ka kuleyliyahaalxanka, isku xirka, cadaadiska boolalka iyo hagaajinta. Soo saarista habka rakibidda, sida waafaqsan shuruudaha badeecada si loo go'aamiyo, guud ahaan, rakibidda saddexdan nooc, marka hore si loo isticmaalo suufka aan biyaha lahayn ayaa noqon doona suufka khamriga aan biyaha lahayn.qaboojiyaha kulka korontadaQaybaha labada dhinac ee dusha sare ee nadiifka ah, saxanka qabow iyo saxanka qaboojinta waa in la farsameeyaa, fidsanaanta dusha sare ma aha wax ka badan 0.03mm, waana nadiif, saddexda nooc ee rakibidda habka hawlgalka waa kuwan soo socda.

1. Alxanka.

Habka rakibidda alxanka wuxuu u baahan yahay in dusha sare ee dibadda ee alxankaQaybta TECwaa in la bireeyaa, saxanka qabow iyo saxanka qaboojintana waa inay sidoo kale awoodaan inay alxamaan (sida: saxanka qabow ee naxaasta ah ama saxanka qaboojinta). Marka la rakibayo saxanka qabow, saxanka qaboojinta iyo qalabka peltier, element peltier, modules-ka qaboojinta thermoelectric, module-ka TEC, saxanka qabow iyo saxanka qaboojinta thermoelectric ayaa marka hore la kululeeyaa, (heerkulka iyo barta dhalaalka ee alxanka waa isku mid), alxanka heerkulka hooseeya ee u dhexeeya qiyaastii 70 ° C iyo 110 ° C ayaa lagu dhalaaliyaa dusha rakibaadda. Kadib dusha sare ee kulul ee qalabka peltier, module-ka peltier, module-ka Thermoelectric, qalabka TEC iyo dusha sare ee lagu rakibayo saxanka qaboojinta, dusha sare ee qabow ee module-ka thermoelectric, qalabka thermoelectric iyo dusha sare ee lagu rakibayo saxanka qabow waxay ku jiraan xiriir is barbar socda iyo dib u soo celin wareeg ah si loo hubiyo in dusha sare ee shaqadu ay si fiican u taabato ka dib qaboojinta. Habka rakibiddu waa mid aad u adag, ma fududa in la dayactiro, waxaana guud ahaan loo isticmaalaa munaasabadaha gaarka ah.

2. Xabagta.

Rakibaadda dhejiska ahthod waa in la isticmaalo dhejis leh kuleyl wanaagsan, oo si siman loogu dahaadhay dusha sare ee rakibidda module-ka qaboojinta Thermoelectric,, saxan qabow iyo saxan qaboojin. Dhumucda dhejiska waa 0.03mm, dusha qabow iyo kulul ee qalabka peltier, peltier cell, module TEC, module thermoelectric iyo dusha rakibaadda ee saxanka qabow iyo saxanka kala firdhinta kulaylka ayaa si is barbar socda loo soo saaraa, si tartiib ahna dib iyo dib ayaa loogu rogaa si loo hubiyo xiriirka wanaagsan ee dusha sare ee taabashada, hawo-qaadistana waxaa la dhigayaa 24 saacadood si dabiici ah loogu bogsado. Habka rakibidda waxaa guud ahaan loo isticmaalaa in si joogto ah loogu hagaajiyo qalabka qaboojinta thermoelectric, cell peltier, qalabka qaboojinta thermoelectric, meesha saxanka kala firdhinta kulaylka ama saxanka qabow.

3. Cadaadiska iyo hagaajinta birta.

Habka rakibidda ee lagu hagaajinayo cadaadiska ee studku waa in si siman loogu dahaadho dusha sare ee rakibiddamoduleka peltiersaxan qabow iyo saxanka kala firdhinta kulaylka oo leh lakab khafiif ah oo dufan silikoon kuleyl ah, oo dhumucdiisuna tahay qiyaastii 0.03mm. Kadibna dusha sare ee kulul eeqaboojiyaha peltieriyo dusha sare ee rakibaadda saxanka qaboojinta, dusha qabow ee qalabka peltier, modules-ka qaboojinta thermoelectric iyo dusha sare ee rakibaadda saxanka qabow waxay ku jiraan xiriir is barbar socda, oo si tartiib ah u wareeji module-ka TEC, module-ka thermoelectric-ka gadaal iyo gadaal, soo saar dufanka kulaylka xad-dhaafka ah, hubi inaad hubiso in dusha sare ee shaqadu ay si fiican u taabato, ka dibna adkee inta u dhaxaysa saxanka qaboojinta, module-ka Thermoelectric, module-ka Peltier, module-ka TEC, module-ka qaboojinta thermoelectric iyo saxanka qabow oo leh boolal, xoogga xidhitaanka waa inuu ahaadaa mid isku mid ah, oo aan xad dhaaf ahayn ama aad u fudud. Culusku waa mid si fudud loo burburin karo qaboojiyaha, iftiinkuna waa mid fudud oo sababi kara in wejiga shaqada uusan taaban. Rakibaaddu waa mid fudud, degdeg ah, dayactir fudud, isku hallayn sare, hadda waa tan ugu badan ee loo isticmaalo codsiga badeecada mid ka mid ah hababka rakibidda.

Saddexda hab ee kor ku xusan ee rakibidda si loo gaaro saameynta ugu wanaagsan ee qaboojinta, codsiga walxaha dahaarka ee u dhexeeya saxanka qabow iyo saxanka qaboojinta, codsiga mashiinka dahaarka kulaylka, si loo yareeyo isbeddelka kulul iyo qabowga, cabbirka saxanka qabow ee qaboojinta heerkulka iyo saxanka qaboojinta waxay ku xiran tahay habka qaboojinta iyo cabbirka awoodda qaboojinta, iyadoo loo eegayo xaaladda codsiga.

Qaybta qaboojinta heerkulka-kuleylka TES1-01009LT125

Imax: 0.9A,

Umax: 1.3V

Qmax: 0.65W

Delta T ugu badnaan: 72C

ACR: 1.19﹢/﹣0.1Ω

Cabbirka: 2.4 × 1.9 × 0.98mm

Module-ka kuleylka ee godka wareegsan iyo dhexe ee TES1-13905T125 Faahfaahinta

Heerkulka dhinaca kulul waa 25 C,

Imax: 5A,

Umax: 15-16 V

Qmax: 48W

Delta T ugu badnaan: 67 C

Dhererka: 3.2+/- 0.1mm

Cabbirka: Dhexroorka dibadda: 39+/- 0.3mm, Dhexroorka gudaha: 9.5mm +/- 0.2mm,

Dhererka Fiilada PVC ee 22AWG: 110mm +/- 2mm

Qaybta kuleylka korontada ee TES1-3202T200

Imax: 1.7-1.9A,

Umax: 2.7V

Qmax:3.1W

Delta T ugu badnaan: 72C

ACR: 1.42-1.57Ω

Cabbirka: 6 × 8.2 × 1.6-1.7mm

Waqtiga boostada: Noofambar-28-2024